Guide to patch panels

Patch panels are tools for organizing and managing connections between computers, switches and other equipment in a LAN. They are designed to facilitate access to network cables, simplify the marking of inputs, increase the reliability of network connections and simplify work with network equipment. Without patch panels, network connections can not only be less orderly, but also less secure, as incorrect connections and errors can lead to malfunctions. Patch panels also simplify network management, allowing you to quickly and easily change connections and perform maintenance of network equipment.

Types of patch panels

Fixed patch panels, or as they are otherwise called, patch panels with fixed ports are the most standard patch panels designed to connect cables directly to the ports on the panel. They can have a different number of ports and are used to provide a structured cabling system that can be easily changed or switched if necessary. Usually, such cheaper patch panels are selected when the structure of the cable network is known in advance and is not subject to change in the future. For example, when, according to the project, all devices in the office are connected with a CAT5 cable, and the modernization of the cable infrastructure is not included in the project. Basically, fixed patch panels are available with one type of connectors, usually RJ45 for category 5 twisted pair.

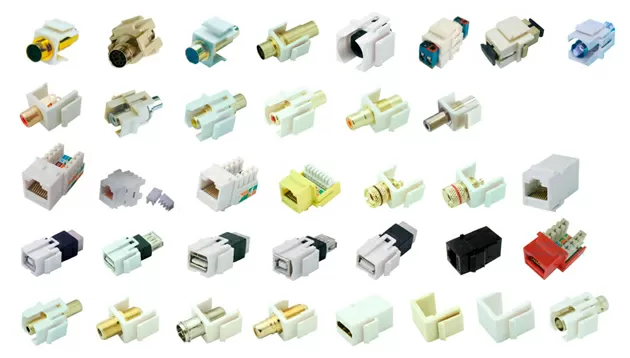

On the other hand, modular patch panels allow you to install Keystone modules for cross-connecting various types of cables. Keystone modules have a standard size and can be installed on special inserts in the panel. Each Keystone module has its own type of connector, for example, RJ-45 for Ethernet or LC for single-mode or multimode fiber. Keystone patch panels allow flexibility in the design of the cable system, facilitate reconfiguration and expansion of the network, adding new types of devices to the server rack, etc. Modular patch panels make it easy to connect various types of equipment within the server rack: servers, A/V receivers, USB keys and drives, analog video surveillance systems, etc.

Patch panels by installation type

There are two types of patch panel installation:

- Wall patch panels – they are installed on the wall in a server or telecommunications room using fasteners that come with the kit.

- Rack-mount patch panels - they are installed in racks for server equipment. In turn, such panels can have a width of 10 or 19 inches.

It should be borne in mind that many rack-mounted patch panels allow wall mounting, but not vice versa.

Port density

Typically, port density is measured by the number of ports per unit height (RU) - the standard height is 19 inches of the panel. The most common patch panels are 24-port ones, since a larger number of ports complicates the process of installing and laying cables in the server rack.

Nevertheless, the industry also offers patch panels with 48 ports per 1U. Models with 10 and 8 ports are also common.

Shielding and protection from EMR

This type of patch panels is especially in demand in conditions of a large number of electrical equipment and electronic equipment in nearby premises, as they allow you to maintain the quality and speed of data transmission. The fact is that even shielded cables in a fixed patch panel are dissolved into cores that are not protected from electromagnetic interference in any way. The general shielding of a small patch panel space can reduce the influence of the electromagnetic background on the conductors, but it cannot in any way affect the mutual influence of cables on each other. It should be borne in mind that for effective protection against EMI, the housing of the patch panel must be grounded: if it is installed on the wall, then on the ground bus, and if in the server cabinet, then on the housing. The fit of the patch panel housing to the steel frame of the server rack cannot be considered effective grounding, since the paint of the housing acts as a dielectric. Usually there is a ground connection on the cases of patch panels.

In general, modular patch panels with shielded Keystone inserts provide a higher level of protection from EMR than fixed ones.

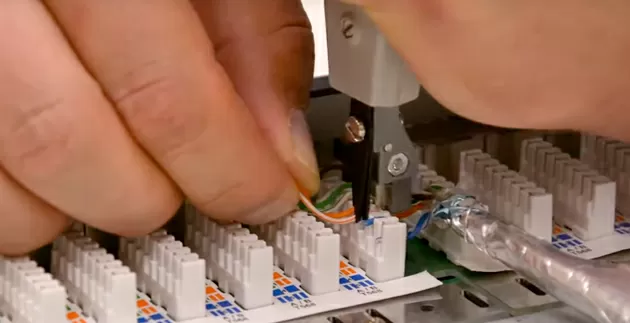

Connection types on fixed patch panels

Various types of fixed clips can be used on patch panels. Here are some of them:

- IDC (Insulation Displacement Connector) is a clamp that uses a wedge-like mechanism to compress a conductor that is fixed in a hole in the clamp. It is one of the most common types of clips on patch panels.

- 110 Block is a clamp that uses an insert with rigid contacts to clamp the conductor. This type of clamp is well suited for thinner conductors.

- The Krone is a clamp that uses a wedge-like mechanism to compress the conductor. It has a more advanced mechanism than IDC, which makes it more reliable.

- BNC (Bayonet Neill-Concelman) is a clamp that is used specifically for coaxial cable. It has two additional screws to secure the end of the cable.

- LC (Lucent Connector) and SC (Standard Connector) are clips that are used for optical cables.

In general, any of these types of clamps can provide good contact if properly installed.

Types of Keystone modules used in patch panels

Keystone modules are small blocks designed to be installed in Keystone sockets on patch panels, sockets on the wall, in drawers and other structures. They are standardized in size and installation types and are compatible with each other.

Advantages of Keystone Modules:

- Easy Maintenance: Keystone modules can be replaced quickly and easily if necessary. For example, if you decide to change the structure of your network, you will not have to replace the entire patch panel entirely, it is enough to replace only a few Keystone modules.

- Versatility: Keystone modules are compatible with many standard Keystone sockets, which allows you to create different configurations of network connections.

- Flexibility: Keystone modules are available in various connection options, such as RJ-45 and RJ-11 for network cables, as well as for connecting coaxial cables or optical cables. There are modules for USB, HDMI, Displayport, MiniJack, etc.

- Compactness: Keystone modules are small and compact, which allows them to be used in confined spaces, such as mounting cabinets and trunks.

- Saving time and resources: Installation of Keystone modules is quick and easy, which saves time and resources during installation and maintenance of network equipment.

There are two main types of Keystone modules: end-to-end, which are connected from the front and back using connectors (the so-called Keystone Coupler and socket, which are connected from the back with a stripped (uncompressed) cable, and from the front with a connector. In turn, end-to-end modules can have both the same connectors in front and back, and different ones. End-to-end connectors will require you to crimp the cable both from the back and from the front side of the patch panel, which will increase the cost of the overall cable infrastructure and add an extra point of failure in the form of a connector inside the patch panel. On the other hand, the replacement of such modules (and they also sometimes fail) is much easier compared to socket ones.

Shielded Keystone Modules

Shielded Keystone modules solve the main task - individual protection of the connected cable from electromagnetic panels along its entire path in the patch panel. If each cable is connected to a shielded module (whether through or socket), it is protected not only from interference sources outside the patch panel, but also from adjacent cables inside the patch panel. Therefore, shielded Keystone modules are used for cables of categories 6, 6a, 7 and 7.1, which are designed to transmit high-frequency data and are sensitive to interference, for example, for 10-gigabit networks.

Shielded Keystone modules can also be used to connect coaxial cables, coaxial cables to antennas, HDMI cables and other cables with similar technical characteristics. It should be noted that for the effective operation of the shielded Keystone module, its housing must have good contact with the foil shield of the cable.

Curved Patch Panels

Curved or folding V-shaped panels are used to connect a large number of cables (24 or 48), usually in 1U, and allow cables to pass in an organized manner into vertical channels above the server rack, which can enter directly into the center of the rack. Due to bending, they distribute the load on the cables more evenly and prevent their fractures and damage, especially from the extreme ports.

This is especially true for thick and heavy symmetrical cables of the 6th and 7th category, HDMI cables and coaxial.

Marking connections

Various cable marking methods can be used on patch panels for easy identification. One of the simplest is to use stickers with port numbers or colored labels. The second method is marking the field located above the port using a marker or special templates. The third method is the use of marking cable sets, which consist of small tags, flexible plastic stickers or shrink tubes.

Please note - the patch panel gives you another place for marking, that is, you can have a marked cable and a marked port on the patch panel, into which another marked cable is connected. And in some cases, it is necessary that these labels be different, for example, when searching for malfunctions. On a network switch, for example, you will not mark the port in any way.

Ron Amadeo

27/03.2023