Li-ion Battery FAQ for Data Center UPS

Lithium ion batteries offer a number of advantages over the traditional valve regulated lead acid (VRLA) batteries commonly used in UPS systems today. Much longer battery life, smaller size and weight, faster recycling times and lower prices have made lithium-ion batteries an attractive energy storage technology. This article provides concise answers to the most common questions about lithium-ion batteries and how they are used by UPS, and is intended to help the user decide which battery technology is best for use in backup power supplies.

What is a lithium-ion battery and how is it different from a lead-acid battery?

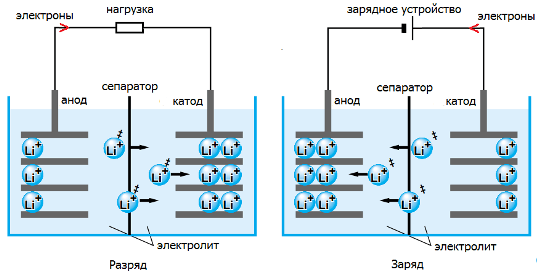

Simply put, a battery is an electrochemical device that stores energy and releases it in the form of electricity. Batteries are usually connected in series, parallel or in combination to achieve any voltage and current. This simple description applies to both lead acid and lithium ion batteries. Each battery contains a cathode (positive electrode) and an anode (negative electrode), which are in the electrolyte. The electrolyte acts as a catalyst for an electrochemical reaction that charges and discharges as ions flow from one electrode to another. It also prevents the backflow of electrons stored at the anode to the cathode inside the battery itself when there is no load. A chemical reaction results in a charge potential (i.e. voltage) difference between the cathode and anode as electrons accumulate at the anode. When a load is connected by wire to the battery terminals, a current is induced that discharges the battery in the form of a stream of electrons (i.e. current) from the anode (negative terminal) to the load and then to the cathode (positive terminal). The chemistry of the battery changes as this ion flow occurs until more electrons are supplied to the anode, causing the battery to drain. The battery can be recharged using an external power source to reverse the flow of electrons through the electrolyte from cathode to anode.

In fig. 1 shows a simple diagram of the flow of electrons inside the battery and between it and the load

So, the fundamental difference between a lithium-ion battery and a lead-acid battery is the chemical composition of the materials used in electrodes and electrolyte. Most modern lithium-ion batteries use metal oxide for the cathode and carbon-based material for the anode. The electrolyte solution is a lithium salt dissolved in an organic solvent. A lead acid battery, on the other hand, uses lead dioxide for the cathode, a lead anode, and a form of sulfuric acid as the electrolyte. This chemistry largely determines the performance of the battery. Table 1 highlights some of the high-level performance differences between the two types of batteries used in UPS applications. However, it is important to understand that there can be large differences in performance between one battery and another of the same type, due to differences in chemistry (e.g., electrolyte and electrode composition) and the general type and quality of materials used, and cell design. This makes it difficult to generalize or generalize the characteristics of lithium-ion batteries, unless their specific application and design are intended.

|

Property

|

Lithium Ion Batteries

|

Lead Acid (VRLA)

|

|

Energy density, W/Kg

|

70 - 60

|

15 - 50

|

|

Life cycle

|

10 - 15 years

|

4 - 6 years

|

|

Number of charge/discharge cycles

|

& gt; 1000

|

200 - 400

|

|

Recharge time, hour

|

1

|

6 - 12

|

This table shows typical performance ranges for the type of battery used in UPS today.

How does the cost of lithium-ion battery systems compare with the cost of lead-acid battery systems when using a UPS?

In general, we can say that the installed cost of a lithium-ion system costs about 1.2-2 times more than lead VRLA for the same power level and run time. The high purchase price was the main reason that the use of lithium-ion batteries in UPSs was so limited. However, it's worth noting that just a few years ago, this difference in cost was 10 times. With this cost reduction, coupled with the high performance benefits, lithium-ion systems are increasingly becoming a viable energy storage option for an increasing number of people. Rising demand, future technological improvements and additional efficiency gains are likely to result in further cost savings. Lead-acid batteries, on the other hand, represent an older, more mature technology with less chance of significant evolution that would significantly change the cost per kWh much further down.

On the operating cost side (OPEX), the lithium-ion system has a clear advantage. This is mainly because the lifespan is roughly double (or more) the lifespan of VRLA systems. Lead-acid batteries may need to be replaced 2-3 times over a 15-year period, while lithium-ion batteries may not need any replacements at all (or perhaps once), which saves a lot of money and reduces maintenance. ... The life of a lithium-ion battery is often calculated for operating conditions at a higher temperature (40 ° C/104 ° F) than lead acid (20-25 ° C/68-77 ° F). This can bring additional savings in operating costs by reducing cooling energy. And since lithium-ion battery systems are 50-80% smaller, the freed up space could be used more productively. The financial value of this can further increase the total cost of ownership of lithium-ion systems. In general, if we consider a 10-year cycle, then UPS systems based on lithium-ion batteries have a TCO 10-40% less than systems with lead batteries.

How safe are lithium-ion batteries?

All types of batteries, by definition, store chemical energy, so each battery, if mishandled (for example, thrown into a fire) or overcharged, has the potential to present a hazard, releasing hazardous materials or igniting a fire. Lithium-ion batteries are considered more unstable due to reported incidents of fire and due to their much higher specific energy combined with greater sensitivity to overcharging. An improperly used lithium-ion battery will more easily reach a `` thermal runaway '' state because it has a lower cell resistance and higher energy storage capacity than a lead-acid battery. However, significant progress has been made over the years, making them safer and much more comparable in terms of safety to other commonly used types of batteries. Chemical changes and improvements in cell packaging have made them more stable. The manufacturing processes have matured and the materials used are more durable. Battery management circuits to prevent overheating or overcharging are well tested and proven to be effective in the field.

The widespread use of lithium batteries in the manufacture of millions of portable electronic devices, smartphones and electric vehicles is the best testament to their high level of safety. Because lithium-ion battery systems are much more sensitive to how they charge and discharge, they all involve a Battery Management System, or BMS, made up of microprocessors, sensors, switches, and associated circuitry. It constantly monitors battery temperature, charge level and charge rate at a cellular level to protect against short circuits and overcharging. The system is also a tool to protect cells from damage, preventing over-low voltage when discharging. BMS provides the UPS and the user with accurate information on battery status, health, and available runtime. While BMS makes lithium-ion battery systems much safer, they are expensive themselves. Lithium-ion batteries do not contain mercury, lead, cadmium or any other material deemed hazardous. Of course, this does not mean that recycling or no recycling has no impact on the environment, but the US government considers them safe enough for landfill.

What is the difference between the types of lithium-ion batteries?

All lithium-ion batteries today use a non-metallic solution containing lithium ions as their electrolyte. This layer is a conductor of electrons, in which current flows between two electrodes, the cathode (+) and the anode (-). The cathode is a metal oxide and the anode is made of a porous carbon material. By changing the type of materials used, you can change the characteristics of the batteries themselves.

Some batteries, for example, are designed to maximize power capacity and provide long run times, measured in hours. They are often referred to as "energy cells."

On the other hand, "power elements" are tuned to provide very high power density (ie power density), but with less energy capacity, when all its power can be supplied to the load in a short period of time. Since UPS systems are typically configured to drain their batteries in a short amount of time (minutes), power cells are used here. Thus, batteries are designed for their intended application. And new chemical technologies are being developed and tested to further push the boundaries of modern lithium-ion battery technology. A common way to differentiate the types of lithium ion batteries is based on their main active chemical material, which gives the battery its unique inherent properties compared to other lithium ion batteries. According to Battery University3, six of the most common types are:

- Lithium Cobalt (LiCoO2)

- Lithium Manganese (LiMn2O4 or “LMO”)

- Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO2 or “NMC”)

- Lithium Iron Phosphate (LiFePO4)

- Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAIO2)

- Lithium Titanate (Li4Ti5O12)

Table 2 shows how different types of chemistry differ from each other in terms of their key attributes.

|

Type of chemistry

|

Orientation to large capacity batteries

|

Orientation to high current battery

|

Security |

Efficiency |

Life Cycle |

Cost |

|

LiCoO2 (LCO) |

Highest |

Medium |

Medium |

High |

Medium |

Medium |

|

LiMn2O4 (LMO) |

High |

High |

High |

Medium |

Medium |

Medium |

|

LiNiMnCoO2 (NMC) |

Highest |

High |

High |

High |

Long |

Medium |

|

LiFePO4 (LFP) |

Average |

Highest |

Highest |

High |

Very long |

Medium |

|

LiNiCoAIO2 (NCA) |

Highest |

High |

Medium |

High |

Long |

High |

|

Li4Ti5O12 (LTO) |

Average

|

High |

Highest |

Highest |

Very long |

Highest |

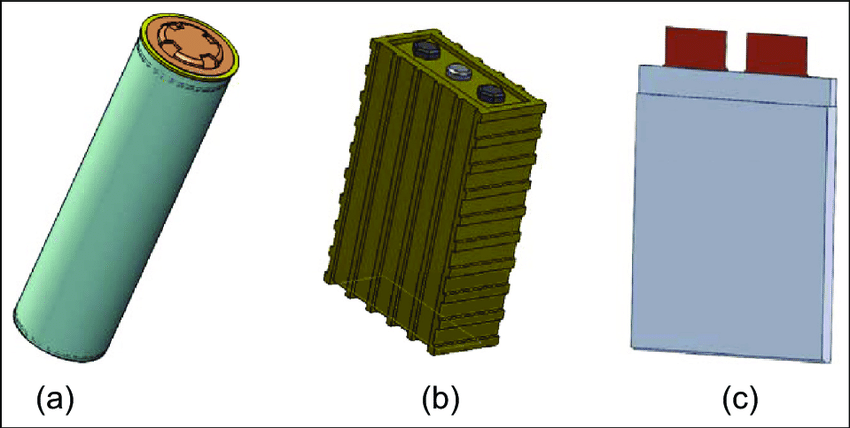

There are other aspects besides chemistry that differentiate one battery from another. Individual battery cells can be packed in different ways and this has an impact on battery performance. There are prismatic bags and cans as well as cylindrical cans. The shape of the elements, as well as the type and quality of materials used in their construction, determines the weight of the battery, energy density, ability to conduct heat, durability (safety) and price.

Type of lithium-ion batteries:

a) - cylindrical, b) - prismatic, c) - bag

But even two batteries of the same type with the same type of chemistry can have different characteristics. UPS manufacturers should select the cubicle design and material quality level appropriate for the intended application.

Can I use lithium-ion batteries with my existing UPS?

Only if the UPS manufacturer says the specific lithium-ion battery in question is compatible. As explained above, lithium batteries come in a wide variety of types, sizes, voltage ranges, form factors, and connector types. These differences must be considered when implementing the UPS inverter, charger, mechanical device and firmware. However, assuming the voltage of the battery system is within the capacity of the UPS, it is possible that the existing UPS could be made compatible by updating the UPS firmware to ensure correct charging procedures, correct run times and accurate reporting of state of charge. Always check with the manufacturer to determine which batteries are safe and compatible.

How do lithium-ion batteries differ in size and weight from lead acid batteries?

Overall, a lithium-ion battery system for a UPS will take up 50-80% less floor space and weigh 60-80% less than a comparable lead acid system. These significant savings are due to the very high specific energy (energy density) found in lithium-ion batteries. The power density of lithium batteries available today ranges from 70 Wh/kg to 260 Wh/kg, with most in the 120-200 range. In comparison, a typical lead acid battery is in the 30-50 Wh/kg range.

How long is the lithium-ion battery life?

Cycle life is the number of times a battery can be fully discharged and charged within a specified temperature range before it needs to be replaced. Once the battery capacity reaches 60-80% when fully charged, this battery becomes unusable and must be replaced. For a traditional sealed lead-acid battery, the service life is 200 to 400 cycles. A typical lithium-ion battery is already rated for more than 1000 cycles. This number depends on several factors, including the specific chemistry used in the design. Some lithium-ion batteries can do more than 5000 cycles today.

What type of service is required?

Lithium ion batteries have very low maintenance requirements. There is no liquid level to measure and maintain (as with valve regulated lead acid batteries). There is no "memory" batteries to worry about, no need to periodically cycle batteries to calibrate their runtimes. And their long service life - 10 years or more - reduces the need to replace them during the entire life of the UPS. By the time the batteries need to be replaced, it will probably be time to replace the UPS as well. The included Battery Management System (BMS) automatically collects and reports all necessary data to accurately understand the health and condition of the battery system, further reducing maintenance time.

Is it necessary to somehow forcibly cool the lithium-ion batteries used in the UPS?

Both lead acid and lithium ion batteries will suffer from high temperatures. In general, however, lithium-ion batteries are less affected by higher temperatures than lead acid batteries. Many of the lithium-ion batteries used in the UPS are rated for higher average temperatures (eg 40 ° C/104 ° F). For both types of batteries, the capacity (ampere-hours or `` Ah '') actually increases with the ambient temperature, however, higher temperatures can limit the available battery life even within the manufacturer's specified operating range. This rarely happens and depends on several factors, including the rate of discharge, the heat dissipation capability of the particular design of the battery in question, and of course temperature. In particular, at higher discharge rates, the battery may reach its thermal limit and shut down before its available capacity is actually used. Most UPSs with lithium-ion batteries do not require additional cooling to maintain the specified longevity, however keeping the battery at a temperature (e.g. 25 ° C) can help achieve the reliability that is specified by the manufacturer.

How should lithium-ion batteries be stored?

Cool storage slows down the aging process of lithium-ion (and other chemical) compounds. Manufacturers recommend a storage temperature of 15 ° C. In addition, the battery must be partially charged prior to storage. Many manufacturers recommend a 20% -40% charge level.

Can I change them "hot"?

No, lithium-ion batteries are inherently not hot-swappable. This is due to their high sensitivity to over and under charge (low impedance).

Are lithium ion batteries environmentally friendly?

There are many different ways you can consider a product to be more environmentally friendly or not than another. Lithium-ion batteries do not contain hazardous materials, while lead-acid batteries contain them (for example, lead). Both types of batteries are recyclable, but lead is now much easier to recycle in most parts of the world than the larger lithium-ion batteries used in UPS and electric vehicles. However, for a complete picture of the environmental impact, consider the entire carbon footprint over the life of a battery. Carbon use accumulates throughout the product's life cycle:

- raw material extraction

- energy for production and transportation

- operating energy to maintain charge and cool batteries

- recyclability and impact on land when it's time to recycle

The analysis shows that operating losses (i.e. the energy used to keep the batteries charged) are by far the dominant driver of the carbon footprint of the UPS and its battery system over a 10-year life cycle. However, there is not much difference in operating loss between the two systems. Which one borders on the other depends on the actual use case. Lithium-ion batteries require less energy to maintain a charge than lead acid batteries. The charge cycle of a lithium-ion battery is 90% efficient compared to 80-85% for a lead acid battery. In addition, lead acid batteries self-discharge at a faster rate than lithium-ion batteries. However, this efficiency gain is offset by the need for Li-ion's Battery Management System (BMS) to protect against short circuits and overcharging, which also consumes energy. Thus, the total operating losses of the two types of batteries are very similar to each other.

Considering that lithium-ion batteries containing landfill-safe materials are recyclable and that their service life is 2-3 times longer than that of lead-acid batteries, it can be argued that lithium-ion batteries are "greener". Note, however, that the recycling rate of lead from lead acid batteries is 99%, with more than 90% of the end of life batteries being recycled.

However, the recycling of lithium-ion batteries, especially those used in larger formats (such as those used in electric vehicles and data center UPS), is not yet mature enough.

Are lithium-ion batteries recyclable?

Yes, they are recyclable. And there are many recyclers who will take small lithium ion batteries. However, at the time of this writing, most smaller size batteries are simply collected and then sent to shredding and incineration, where some of the materials used in production can be recovered for later use. But most of the material from lithium-ion batteries ends up in landfills. From a purely financial standpoint, recycling lithium-ion batteries to recycle very small amounts of lithium metal and other more common but less valuable metals (aluminum, nickel, etc.) is not worth the effort.

Research continues to improve recycling economics, and governments are beginning to encourage, inter alia, or explicitly require the collection and proper recycling of batteries. Recycling larger format lithium-ion batteries (such as those used for electric vehicles and data center UPSs) is more challenging. As of this writing, there are several companies that can recycle large lithium ion battery systems. The market is immature. So far, very few of these batteries are exhausted.

Are there any special restrictions for their transportation?

Yes, regulations vary by region, but a good guide to understanding air travel restrictions and requirements is the International Air Transport Association (IATA) and its Dangerous Goods Regulations (DGR) 7, which describe air travel mandates by size, weight and quantity.

Remember that all battery types have certain requirements and limitations.

Do I need a battery management system when using Li-ion?

Yes, and it's already included in every Li-ion battery system. As stated, lithium-ion batteries are very sensitive to overcharging, short circuiting, and over-discharge. The control system constantly monitors each battery cell and manages the charging system to ensure these conditions do not occur or result in damage or overheating.

In case you are designing an uninterruptible power system using lithium ion cells without BMS, you must install such a system separately.

How does the recharge time compare to lead acid batteries?

The charging time in a UPS is determined not so much by the battery as by the power of the rectifier, so the time to reach 80% state of charge (SOC) will be more or less the same for both types of batteries. But it takes less time for a Li-ion battery to go from 80% to 100% state of charge.

In case we are not limited by the power of the UPS charger, of course a lithium-ion battery is much better: it will reach 100% charge in 30-60 minutes, and this will be 5-10 hours less than in the case of a VRLA battery the same capacity.

Conclusions

Lithium-ion battery technology has evolved to be viable and safe for use in large devices such as electric vehicles and data center UPSs. Their unique chemistry and cell packaging offer advantages over more traditional battery alternatives. For UPS applications, lithium-ion batteries are smaller, lighter, charge faster, and have twice or longer calendar life than lead acid batteries, the dominant energy storage technology used in battery backup today.

Li-ion is arguably a greener solution. And, perhaps surprisingly, given the higher acquisition cost, it has a lower total cost of ownership (TCO).

Ron Amadeo

07/07.2020