How the oil and gas industry uses IoT

Like many traditional industries that use long-standing methods of operation, the oil and gas sector has been rocking for a long time before it started using IoT technology.despite having devices on drilling rigs, pipelines, and wastewater treatment plants for decades, the mining industry has only recently started working with modern IoT.

According to Mark Carrier, Director of oil and gas development at RTI, which makes software for connecting industrial companies, part of the problem is related to interoperability. Energy companies are most comfortable working with the same suppliers they used to work with, but thanks to this trend, they don't have much incentive to develop data exchange between platforms.

Kristin Bowles, Intel's Vice President at the IoT group, said older systems that are still used in the industry are difficult to replace. “The biggest challenge they face is aging infrastructure and how they get to a more standardized version, " she said.

However, the changes are happening in part because energy prices have fallen sharply in recent years. Oil companies have sought to reduce costs, and one of the easiest places to do this is integration and automation. On a typical oil well, the drilling process can use the products of 70 different manufacturers: sensors that cover parameters such as flow rate, temperature, pressure, azimuth, tilt angles, and various components of the drill itself. Until recently, all of them had to be controlled independently.

An IoT solution that can link all these different data streams together has recently become an attractive option for companies looking to minimize human error and get real-time information from a wide range of instruments present on an average oil rig.

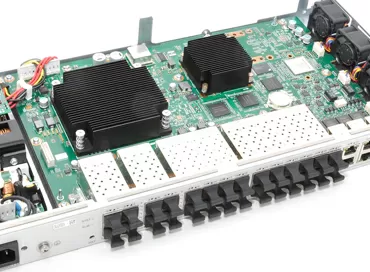

These streams are numerous, with a large number of vertically unique sensor types and endpoints. Pulsed mud telemetry uses a module in the drill head to create small fluctuations in mud pressure to pulse information to a receiver on the surface. Temperature and pressure sensors operating in the extreme environment of an active well can use a reinforced RS-232 cable running back to the surface to transmit data.

Andre Kinter, chief analyst at Forrester Research, said that the wide range of technologies, manufacturers and standards used at any given oil and gas facility is a product of fierce competition between major traditional industry players. ABB, Siemens and Rockwell have invested a lot of effort to maintain the interoperability of their products. And these companies have also moved with the times, while traditional it companies like HP and Dell have had relatively little success selling their solutions to energy companies.

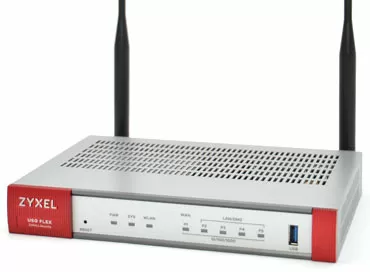

Edge computing is a particularly important technology among oil and gas companies, given the remoteness of some sites, the potentially insufficient local network infrastructure, and the associated difficulties in laying cables. Oil drilling applications are not tolerant of latency, and it is impractical to drive data from a local facility to a Central office. Simply put, it is much easier to perform some computing work near the end point, using a small, perhaps even mobile data center.

The main use cases for oil and gas IoT are preventive maintenance and centralized control. All of them depend on transmitting information from a variety of sensors installed on the rig and transmitting them for analysis to the local data center or to the cloud. Sensors on the rig, as already mentioned, use a wide range of wired and wireless technologies, including proprietary ones, to get information in a convenient form.

Transferring data from remote locations to the cloud or data center also causes difficulties in the oil and gas industry. Where coverage allows, cellular communication is for wireless data transmission, but this is often not an option for ocean oil rigs. Some companies use satellite communications for this purpose, while others run underwater fiber-optic cables directly to their offshore facilities.

Using modern machine learning methods, the oil and gas industry can achieve success in several areas. At the drilling level, of course, smarter systems can synthesize information from all the sensors involved to create a much more accurate and timely picture of how accurately the well is being drilled, how

Ron Amadeo

21/10.2019